How to enhance elasticity and fit in sock manufacturing

In the sock manufacturing industry, elasticity and fit are key factors affecting wearing comfort and functionality. As a professional sock manufacturer like Zhuji City Lilong Import and Export Co., LTD, we are committed to in-depth research and implementation of a variety of advanced technologies and material selections to ensure that our products provide an excellent wearing experience while meeting consumer needs.

Material selection and combination

Application of elastic fibers

In the manufacturing process of socks, the selection of materials is the basis for enhancing elasticity and fit. We prefer spandex as the main elastic fiber. Spandex is known for its extremely high elasticity and can quickly return to its original shape after stretching, thus ensuring that the socks can fit tightly to the foot, prevent slipping or wrinkling, and provide lasting comfort.

Innovation of composite materials

To further improve the fit of socks, we use spandex in combination with other materials. For example, the combination of spandex with materials such as cotton, polyester or nylon not only maintains the comfort and breathability of socks, but also enhances the elasticity and durability of socks. The application of this composite material enables the socks to better adapt to the movement needs of the feet in different sports occasions, improving the overall functionality and use experience.

Optimization of design structure

Three-dimensional cutting technology

During the design stage of the socks, we use three-dimensional cutting technology to design according to the natural shape of the foot. This method enables the socks to better fit the curve of the foot and significantly reduce unnecessary looseness and sliding. Through precise three-dimensional cutting, we ensure that the socks provide the best comfort and stability when worn, meeting consumers' high standards for comfort.

Strengthen the design of elastic areas

Adding elastic design to specific areas of the socks (such as ankles, arches, etc.) can significantly improve the fit of the socks. We use a higher proportion of spandex in these key areas to ensure that the socks can better support the feet during exercise, prevent sliding and improve comfort. This design not only enhances the functionality of the socks, but also improves the overall aesthetics, meeting consumers' dual needs for fashion and function.

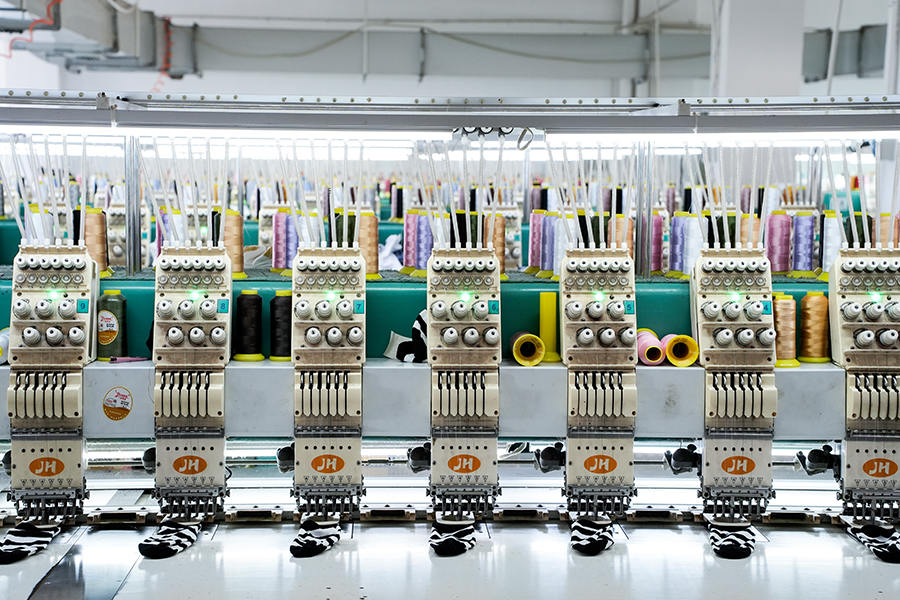

Advanced weaving technology

Diversification of fabric structures

In the production process of socks, we use advanced weaving technology, including a variety of fabric structures such as plain weave, rib and mesh weaving. These different knitting methods not only affect the look and feel of the socks, but also directly affect the elasticity and fit of the socks. For example, rib knitting can provide better elasticity and fit, especially suitable for sports socks that require a high degree of fit.

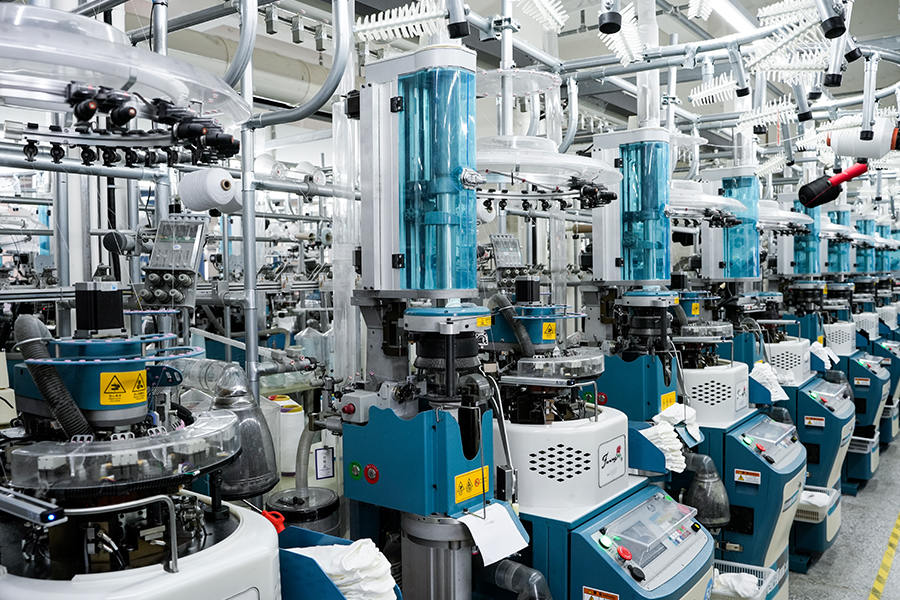

Application of 3D knitting technology

With the development of science and technology, 3D knitting technology has gradually been applied to sock manufacturing. Through 3D knitting, we can achieve different elasticity and fit in different parts of the socks. This technology allows the socks to be reasonably supported at all positions of the foot, improving the overall comfort. 3D knitting not only optimizes the functionality of socks, but also promotes the innovation of sock design, making it more in line with the needs of modern consumers.

Innovation in production technology

Precision stitching process

In the production process of socks, the accuracy of the stitching process is crucial. We use advanced flat seams and hemming technology to ensure that the seams of the socks are flat and smooth, thereby effectively reducing friction and pressure on the feet. This refined process not only significantly improves the durability of the socks, but also enhances the overall fit of the socks, allowing consumers to experience unparalleled comfort when wearing them.

Strict quality control system

In order to ensure that every pair of socks can meet high standards of elasticity and fit, we have implemented a strict quality control system during the production process. Through regular sampling and performance testing, we can promptly detect and correct potential problems in production, thereby ensuring the high quality of the final product. Our quality control not only covers the selection of raw materials, but also extends to every link of production to ensure that every pair of socks can achieve the best balance between functionality and comfort.

Personalization and humanization of design

We are well aware that every consumer has different needs for socks. Therefore, our design team focuses on the combination of personalization and humanization. Through market research and consumer feedback, we continue to optimize the design of socks to ensure that they can meet the needs of different consumers in terms of appearance and function. Whether it is sports socks, casual socks or business socks, we can provide a variety of styles and functional options to help consumers find the most suitable socks for different occasions.

English

English

Español

Español